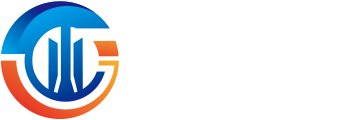

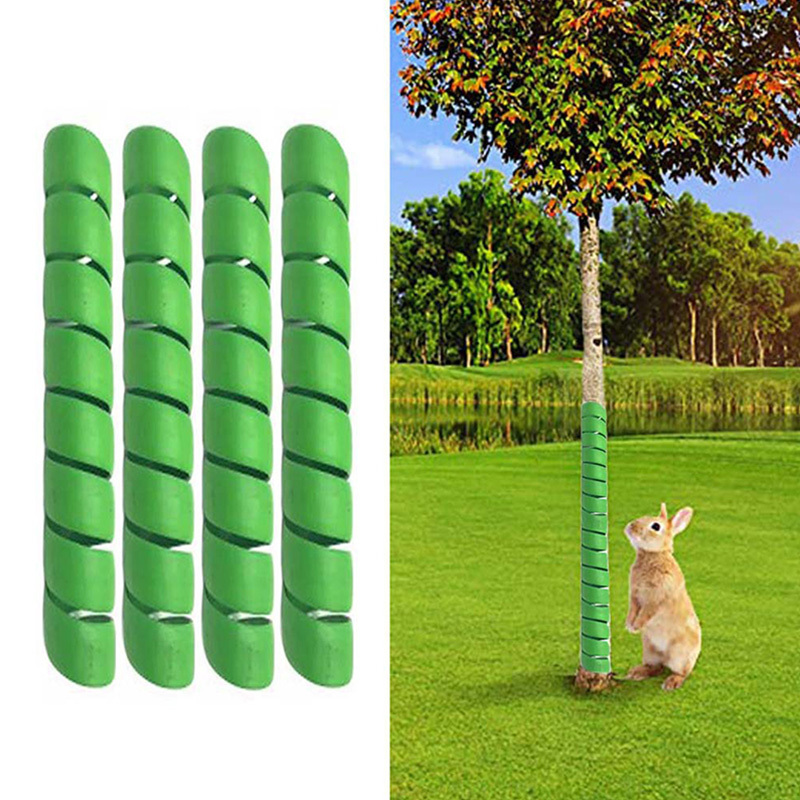

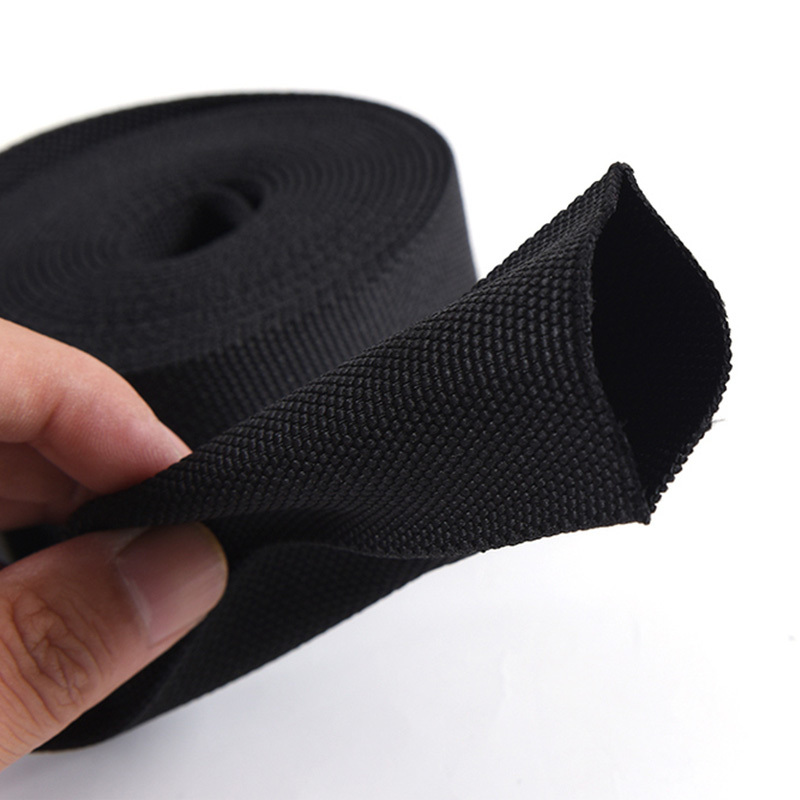

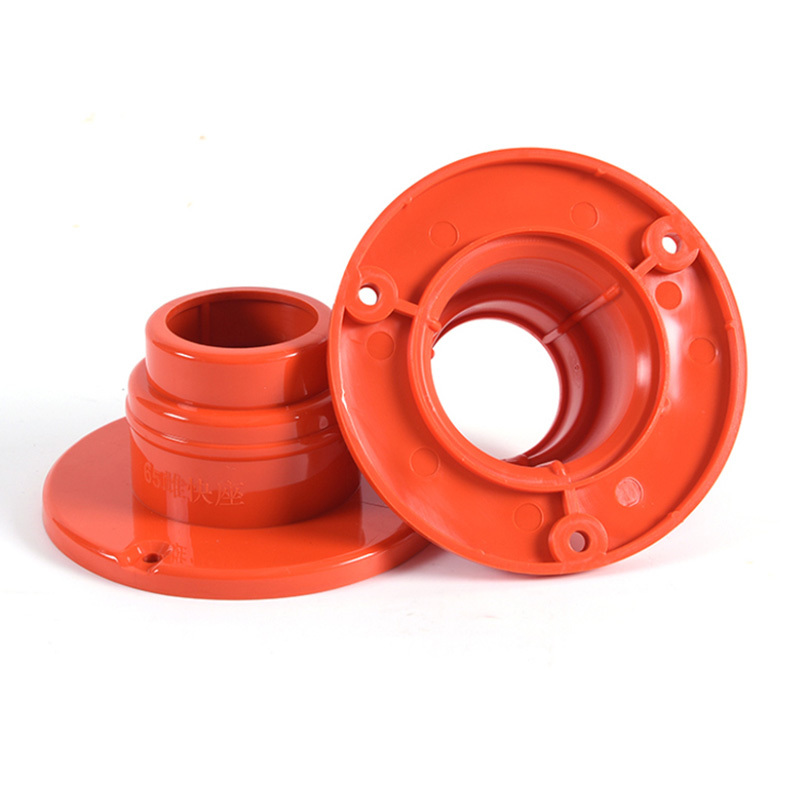

Injection molded parts

Category:

Product Information

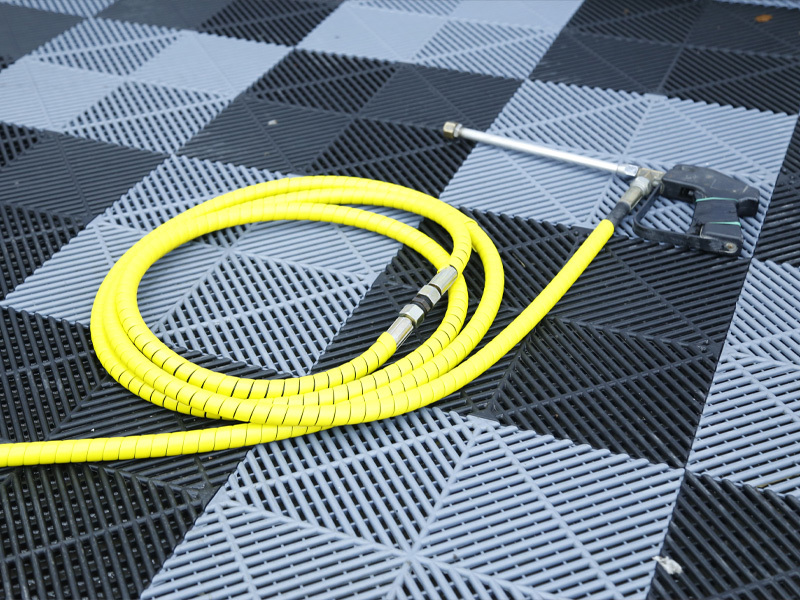

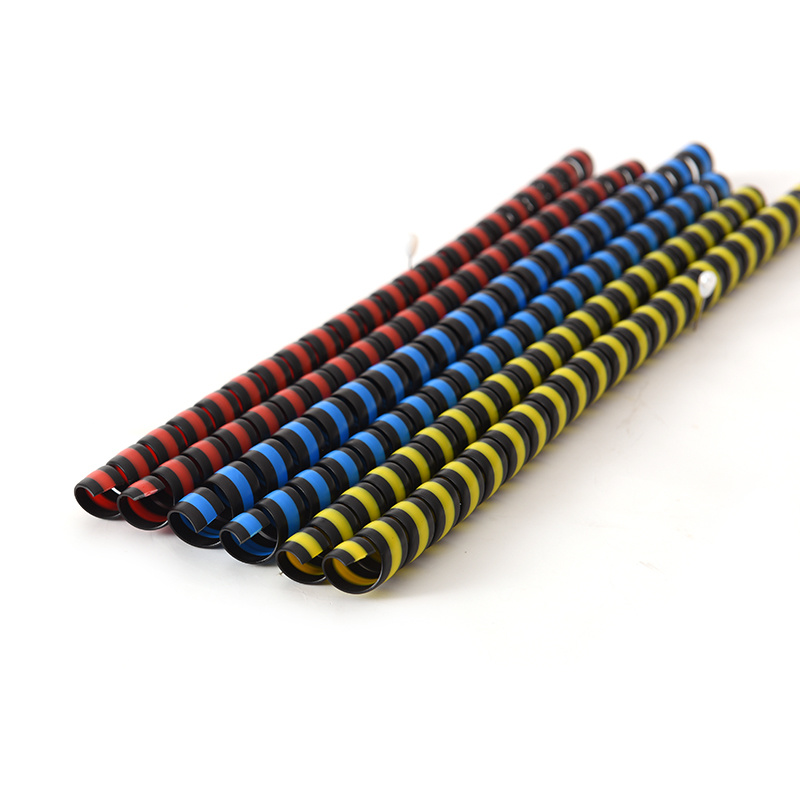

Injection molding products can be seen everywhere in our daily life and have many remarkable characteristics.

The characteristics of injection molding products include: First, it can produce products with complex shapes and high precision to meet various design requirements. Secondly, it has good consistency and repeatability, and can produce products of the same specification on a large scale. Furthermore, the production efficiency is high, and a large number of products can be produced quickly. In addition, injection molding products also have good mechanical properties and durability, and can adapt to different environments.

However, in order to obtain high-quality injection molding products, the purchase of raw materials is very important. Here are some points to consider when purchasing injection molding raw materials:

One is the performance requirements. According to the specific use of injection molding products and performance requirements to choose the right material. For example, for products that require high strength, materials with excellent mechanical properties should be selected; if the product is to be used in a high temperature environment, high temperature resistant raw materials are required.

The second is mobility. Good fluidity can ensure that the material can fill the mold evenly during the injection molding process, reducing the generation of defects.

Three is stability. Raw materials should have stable chemical and physical properties and not be prone to deterioration or degradation during storage and processing.

Four to consider the cost. On the premise of meeting the product performance requirements, try to choose raw materials with reasonable cost to ensure the market competitiveness of the product.

Five is the credibility of suppliers. Choose reputable and reliable quality suppliers who can provide a stable supply of raw materials and high-quality technical support.

Six are environmental factors. With the increase of environmental awareness, priority should be given to environmentally friendly raw materials to comply with relevant environmental regulations.

Seven is workability. Raw materials should be easy to process, including melting, injection molding and other processes to improve production efficiency and reduce costs.

In the actual purchase, you can understand the advantages and disadvantages of materials from different suppliers through performance testing and comparison. At the same time, conduct in-depth communication with suppliers to obtain more information and suggestions on materials. You can also refer to the experience and cases of the same industry and learn from the successful selection experience of others.

In short, injection molding products have unique advantages, and the correct purchase of raw materials is a key step to ensure the quality of injection molding products. It is necessary to comprehensively consider various factors to find the most suitable raw materials for specific injection molding products, so as to produce high-quality, high-performance and market-competitive injection molding products.

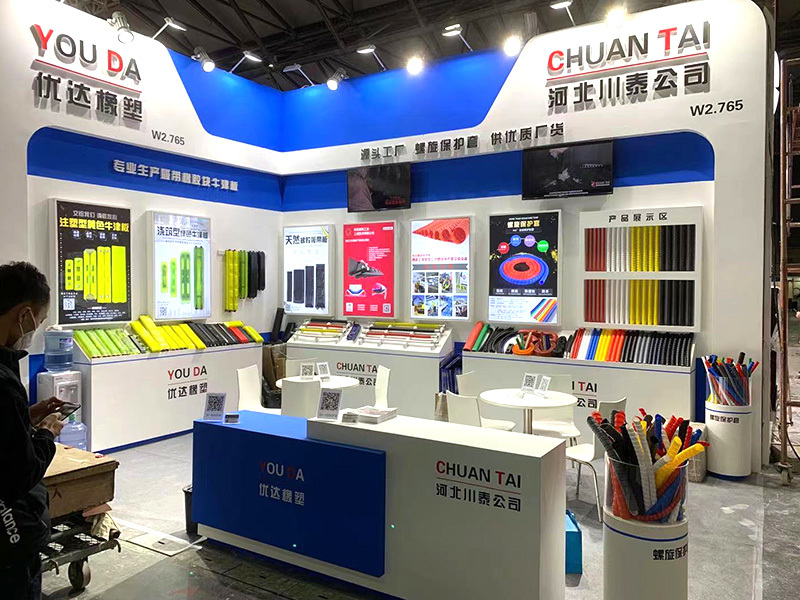

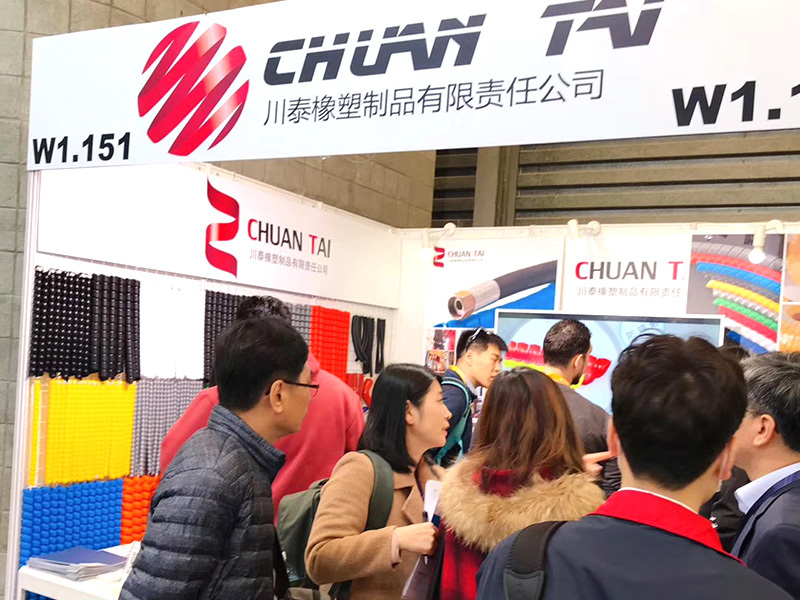

Production strength

Related Products

Key words: