Molded parts

Category:

Product Information

Molding is a common processing technology, widely used in various manufacturing industries. It is characterized by processing raw materials such as plastics into finished products of the desired shape under certain temperature and pressure conditions. The molding process has the following characteristics and scope of application:

Features

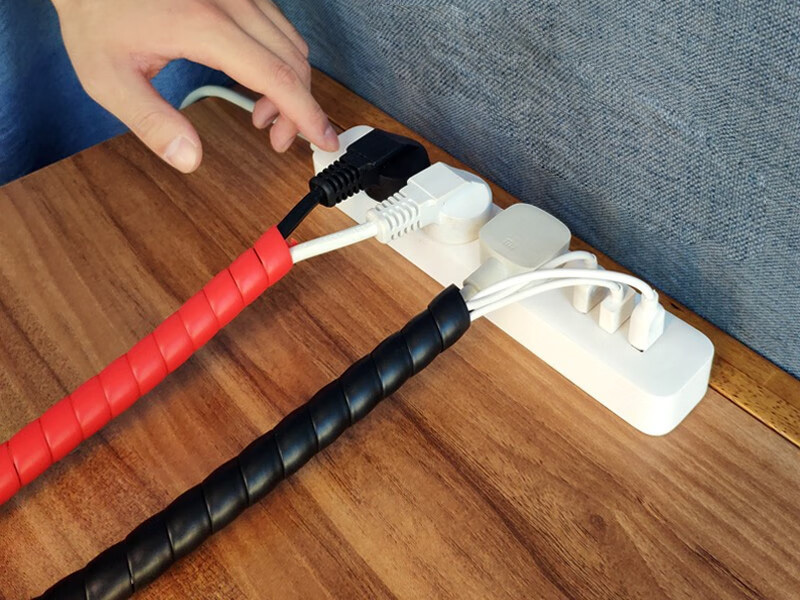

High precision: The molding process can produce high-precision, fine-structured products, which are suitable for occasions with precise requirements on product size and shape, such as electronic product shells, engineering models, etc.

High production efficiency: molding can achieve mass production, can produce a large number of products of consistent quality in a relatively short period of time, suitable for industries that require mass production, such as auto parts, home appliances, etc.

Low cost: Compared with other manufacturing processes, the cost of the molding process is relatively low, with high cost-effectiveness, suitable for the pursuit of cost-effective production occasions.

Smooth surface of the product: The surface of the product manufactured by the molding process is flat and smooth, and does not require additional surface treatment. It is suitable for products with high surface quality requirements, such as cosmetic packaging, plastic boxes, etc.

High design freedom: The molding process is suitable for product design of various shapes, sizes, and complexities, which is conducive to the personalization and customization of products, and is suitable for designing diversified products, such as toys, daily necessities, etc.

Scope of application

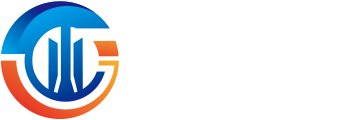

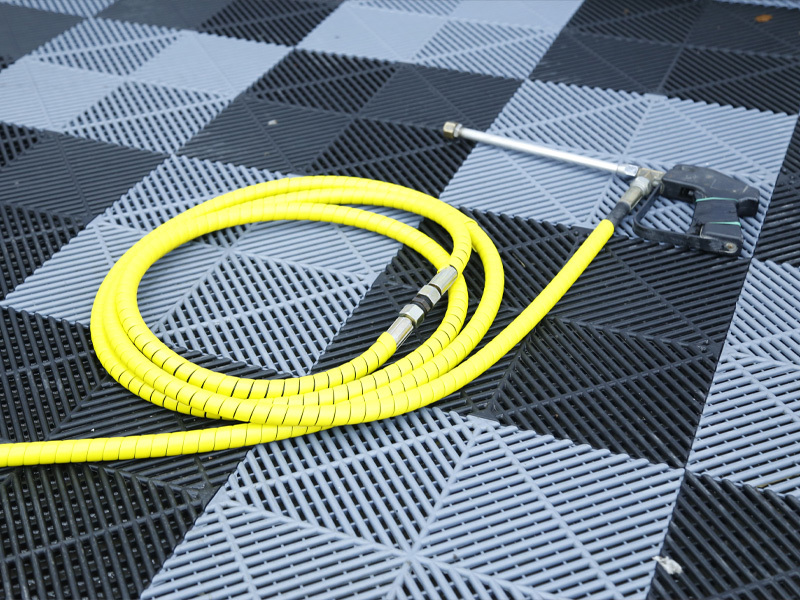

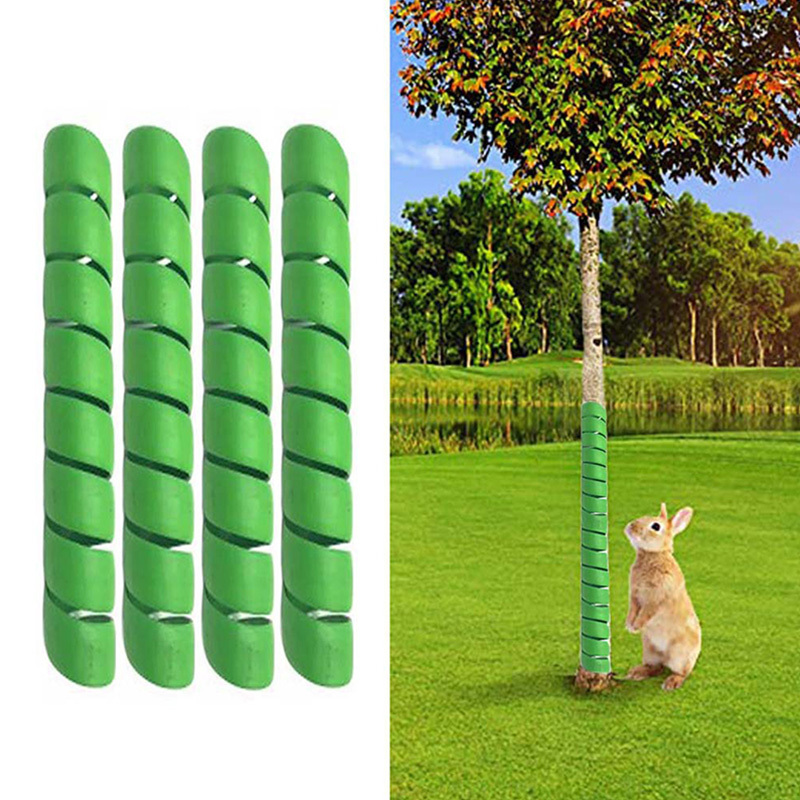

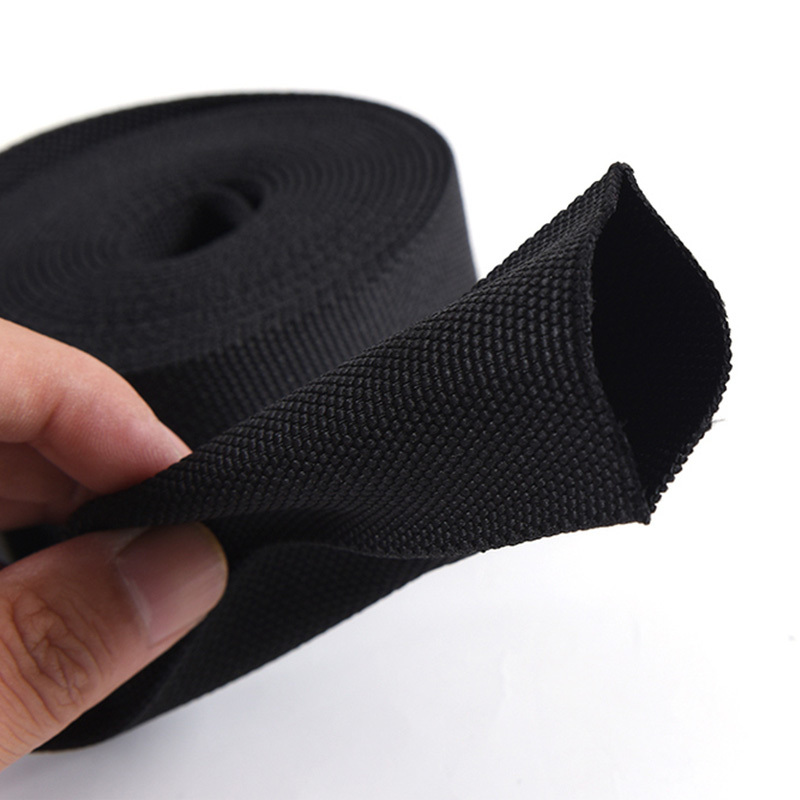

Plastic products industry: molding process is widely used in plastic products industry, such as plastic packaging, plastic parts, plastic toys, etc.

Electronic product manufacturing: Electronic product housings, accessories, etc. are often molded to achieve high precision and appearance requirements.

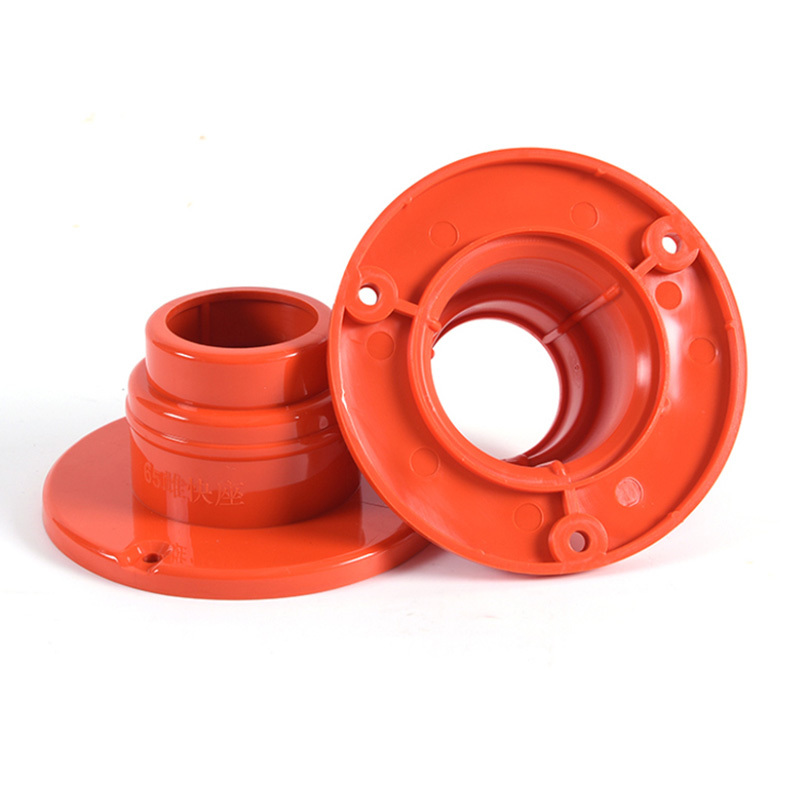

Auto parts: Many plastic parts in the automotive industry are manufactured through a molding process to meet the quality and cost requirements of automobile manufacturing.

Medical devices: The shells and accessories of some medical devices use a molding process to ensure that the surface of the product is smooth and hygienic.

Furniture production: Some plastic accessories and shells in furniture can also be manufactured through the molding process to improve production efficiency and product quality.

In general, the molding process has the characteristics of high precision, high production efficiency, low cost, smooth surface and high design freedom. It is suitable for plastic products, electronic products, auto parts, medical devices, furniture and other industries. One of the commonly used manufacturing processes.

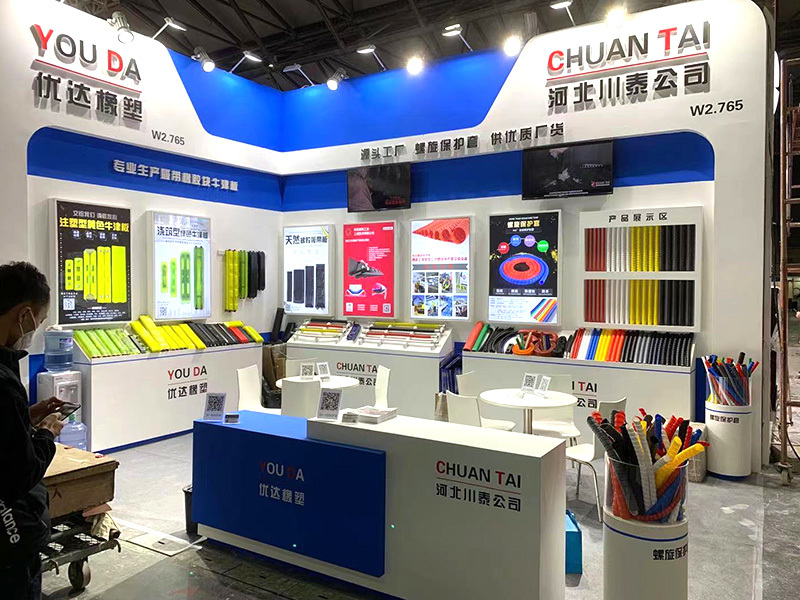

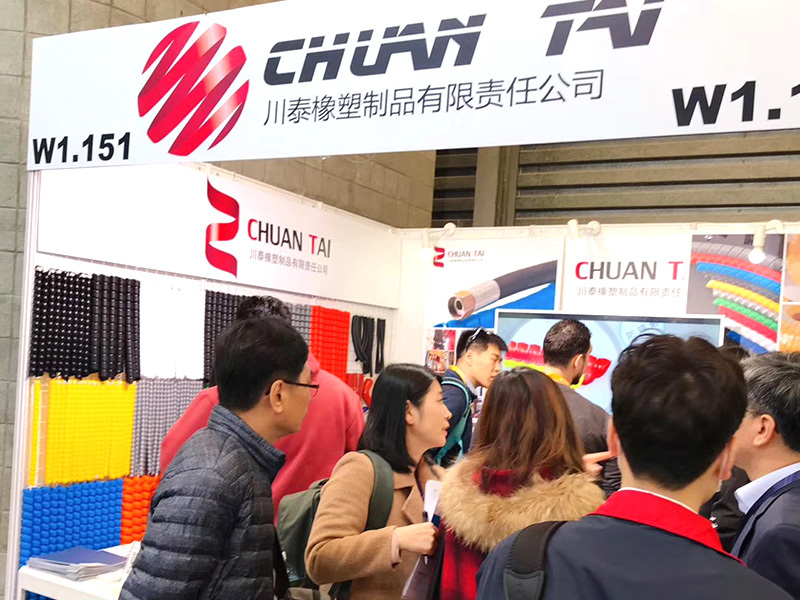

Production strength

Related Products

Key words: