Safe Protector_Flame-retardant Version(SP Fl)

Category:

Parameter

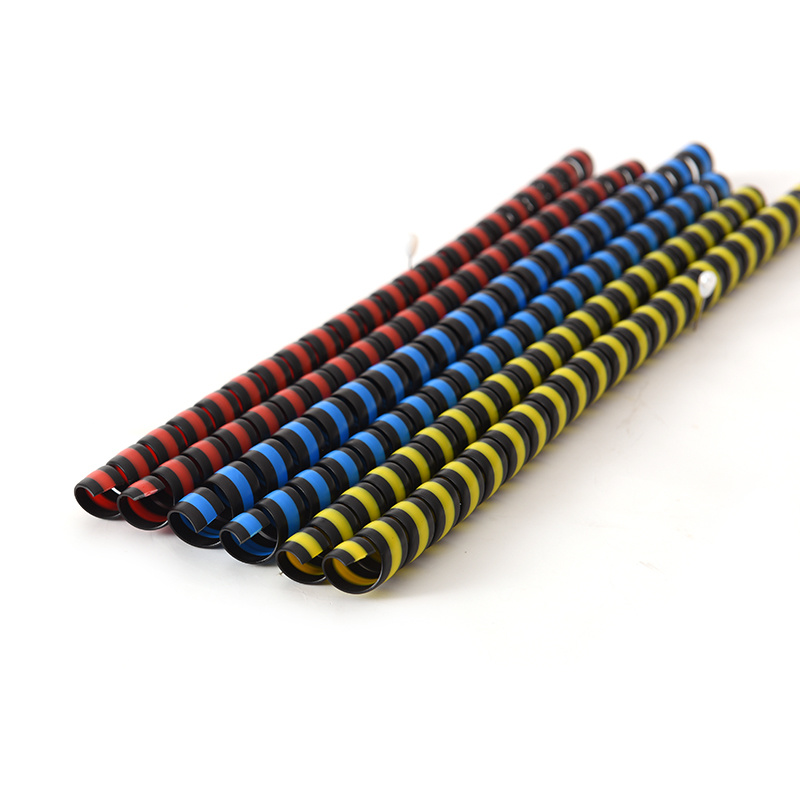

Product length: 2 meters, 12 meters, 15 meters, 30.5 meters, 20 meters, 25 meters, 50 meters, 60 meters, 61 meters, 100 meters, 200 meters Product color: black, yellow, red, blue, white, green, gray, silver gray, orange, orange, support color customization. Product packaging: open carton, woven bag, regular carton, support custom carton printing LOGO Support customized flame retardant products, has passed UL94/V0/V2 detection. Easy installation, beautiful installation, wear resistance will increase the service life of the pipe Product shape, inner diameter, thickness, width support custom.

Product Information

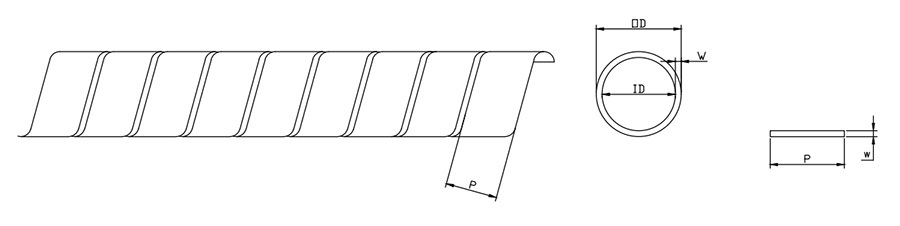

Electronic chart, ID/OD/P/W and other desired data E-mail, Whats, WeChat, sending

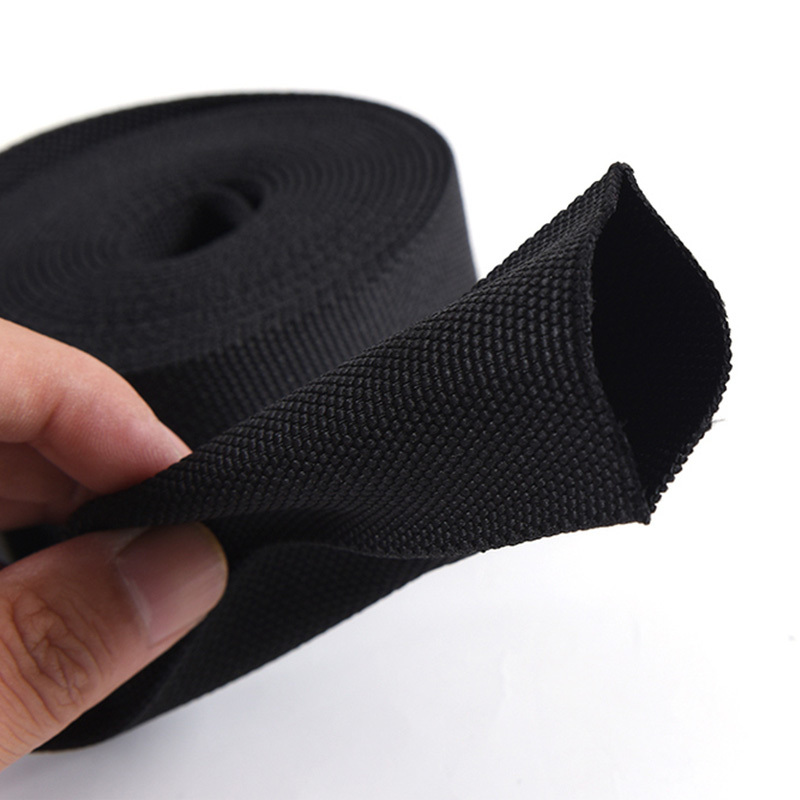

Spiral protective sleeve (flame retardant)

Low temperature resistance -50 ℃, high temperature 80 ℃, short time (high temperature 100 ℃)

Tensile properties

Test basis: GB/T1040.2-2022

Tensile modulus 1131(MPa)

Tensile strength 25.37(MPa)

Elongation at break 143(%)

Wear resistance test, mass loss, 0.0674g

Ultraviolet anti-aging, detection basis: GB/16422.3-2022

Lamp type: UVB-313: test time 200h

Irradiance W/(㎡.nm)(3100mm)/Light 0.67

Black temperature (60 ℃)

Exposure cycle (h)

Ultraviolet aging (no visible change in test results and appearance)

has passed the rohs test, in line with eu standards.

Low density 0.91g/com3 (floating in water)

Oil resistance, acid and alkali resistance.

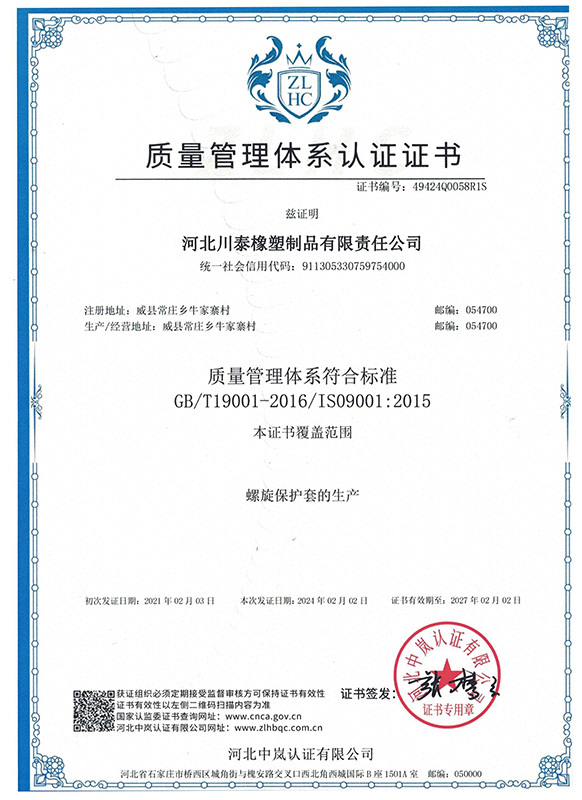

Our company has passed the 9001 certification

Spiral protective sleeve flame retardant type, the use of hot winding shaped extrusion process made of spiral sheath.

It has the following features and advantages:

• Flame retardant performance: has passed UL94,/V0/V2 level can effectively prevent the spread of flame, reduce the risk of fire.

Good wear resistance: can reduce the external friction on the internal product wear.

• UV: in the outdoor environment can effectively resist the erosion of ultraviolet rays.

• Anti-aging: delay the aging process of the product and extend the service life.

• Corrosion resistance: It has strong corrosion resistance and can protect internal products in different chemical environments.

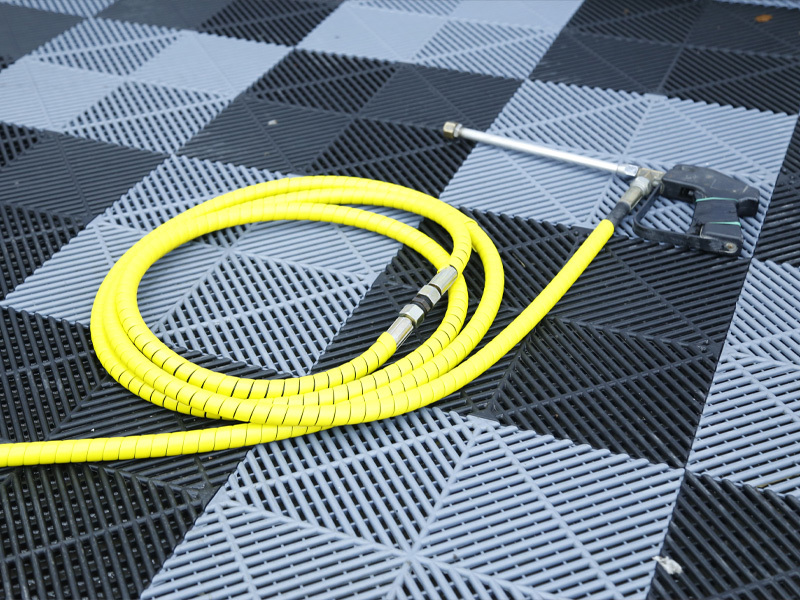

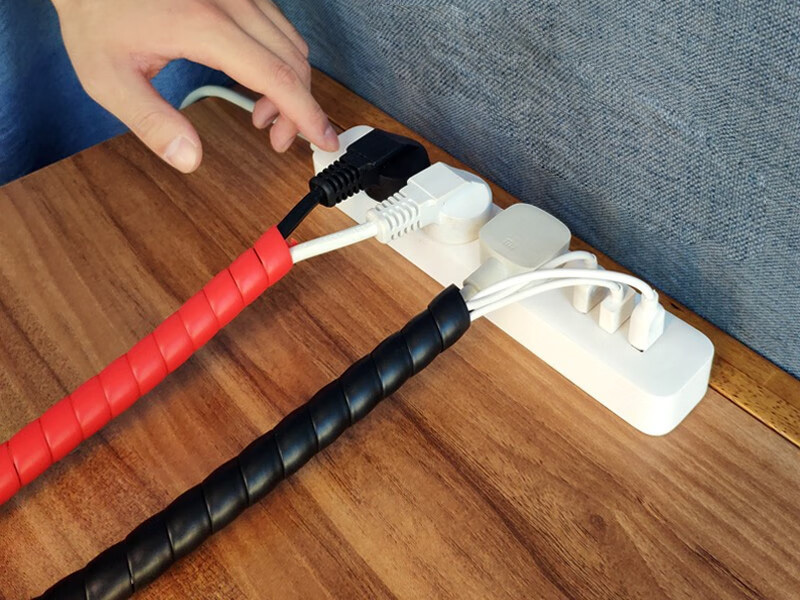

Its wide range of applications, commonly used in coal mine support, wire and cable, fear of fire, hydraulic hose, wire, cable and other products of the external. After installing the spiral protective sleeve, it can not only improve the overall appearance, but also extend the life of the internal product by more than 3 years.

The flame-retardant spiral protective sleeve is easy to install, with better wear resistance and aesthetics; it has strong aging resistance and corrosion resistance, and can more effectively protect the outer surface of hydraulic hoses, wires, cables and other products against aging and friction; At the same time, it has more excellent, more convenient, more environmentally friendly and energy-saving effects.

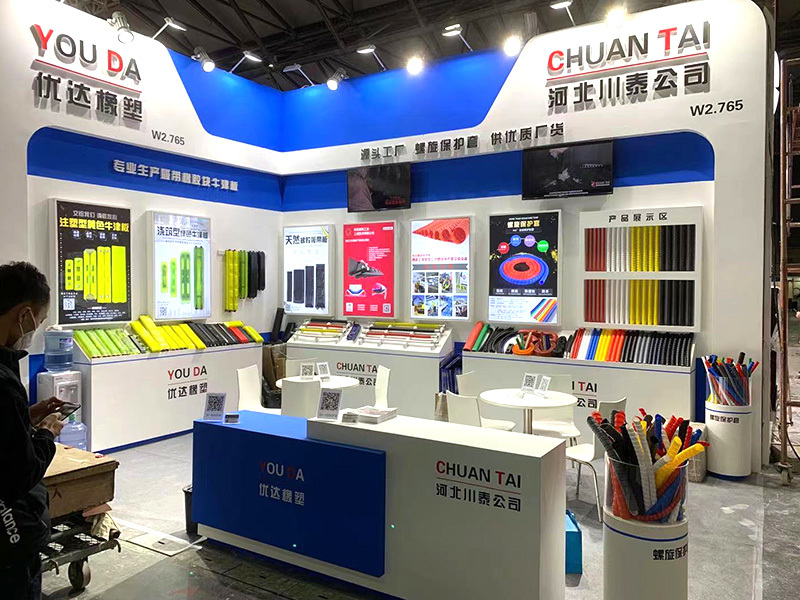

24 production lines of spiral protective sleeve equipment, 5 batching equipment and 3 cooling equipment

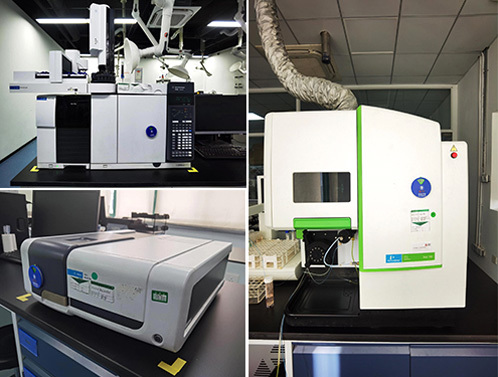

ROHS test

|

ROHS(ROHS Test Equipment) Sample name: spiral protective sleeve Sample number: 2403001531-2 Description: Black solid Test results: lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB)s), polybrominated diphenyl ethers (PBDEs), phthalates (such as dibutyl phthalate (DBP), butyl benzyl phthalate (BBP), di (2-ethylhexyl) phthalate (DEHP) and diisobutyl ortho-benzoate (DIBP))The test results comply with the limit requirements of Amendment Directive (EU)2015/863 to Annex 2 of EU ROHS Directive 2011/65/EU. Tested to meet testing standards * Detailed test data shall be subject to the company's test report |

|

|

Low temperature test

|

High and low temperature box (low temperature test equipment) Test items: low temperature test Test basis: GJB 150.4A-2009 Testing equipment: high and low temperature humidity and heat test chamber, model: ASR-50ET Testing conditions:-50 ℃, after 24h aging, fill the sample with customer-supplied filler, and freely drop the impact sample from 100mm with 300g heavy hammer under -50 ℃ environment. Test results:The sample has no crack or fracture after testing and meets the inspection standard. * Detailed test data shall be subject to the company's test report |

|

|

High temperature test

|

Oven (high temperature test equipment) Test items: high temperature test Test basis: GJB 150.3A-2009 Testing equipment: oven, model: FD56 Testing conditions: 100 ℃, after 24h aging, fill the sample with customer-supplied filler, and freely drop the impact sample from 100mm with a 300g heavy hammer at 100 ℃. Test results:The sample has no crack or fracture after testing and meets the inspection standard. * Detailed test data shall be subject to the company's test report |

|

|

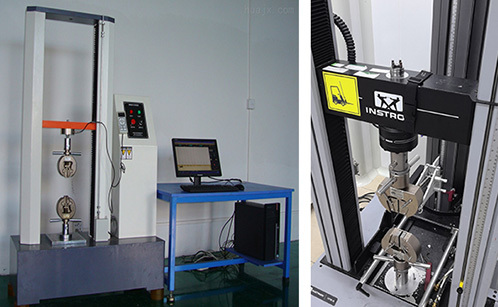

Tensile performance test

|

Tensile machine (tensile performance testing equipment) Test items: tensile properties Test basis: GB/T1040.2-2022 Testing equipment: universal material testing machine, model: 34TM-30 Digital micrometer, model: 0-25mm Detection conditions: style specification: 1A clamp distance: 115mm Gage: 75mm Speed: Modulus stage 1 mm/min Other stages: 50 mm/min Test conclusion:Tensile modulus (MPa):1.13x103 Tensile strength (MPa):25.4 Elongation at break (%):1.4x102 Tested to comply with GB/T1040.2-2022 testing standards * Detailed test data shall be subject to the company's test report |

|

|

Wear test

|

Abrasion testing machine (abrasion test equipment) Test items: wear resistance test Test basis: GB/T 5478-2008 Testing equipment: wear resistance testing machine, model: GB-7012-T Electronic balance, model: ME204 Test condition: load: 1000g Revolutions: 1000r Grinding wheel type: H18 Speed: 60rpm Test results:Quality loss 0.0674g tested in line with testing standards * Detailed test data shall be subject to the company's test report |

|

|

Ultraviolet test

|

UV box (UV aging test equipment) Test items: UV aging Test basis: GB/T16422.3-2022 Testing equipment: UV aging test machine, model: QUV/Spray Test conditions: lamp type: UVB-313; Test time: 200h Irradiance W/(m2nm)(310nm) illumination 0.67 Blackboard temperature (℃) illumination 60 condensation 50 Exposure period (h) light 4 condensation 4 Test results:No visual change in appearance After testing, it meets the inspection standard * Detailed test data shall be subject to the company's test report |

|

|

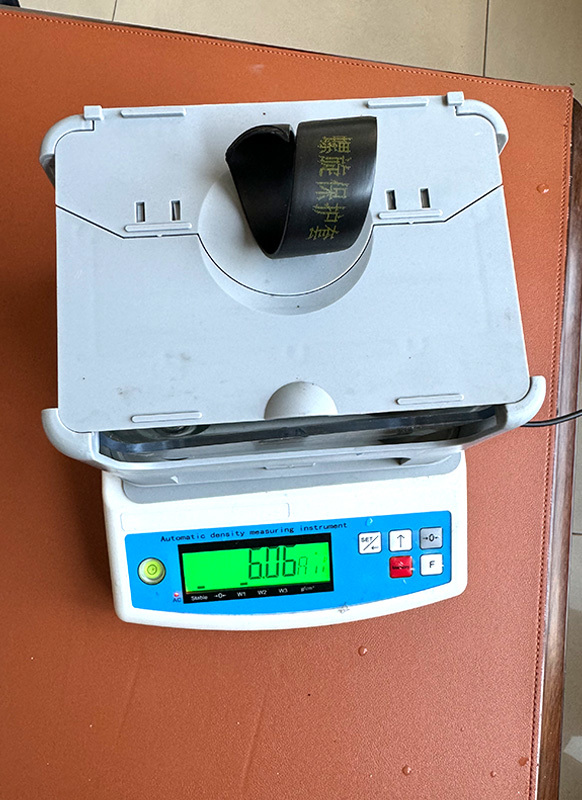

Product low density test: low density 0.9g/com³ (floating in water)

Only pure raw materials (new materials can reach the data)

ISO9001 certification

Raw material warehouse

Finished product warehouse

Spiral protective sleeves (flame retardant type) are widely used in excavators, pump trucks, loaders, road rollers, mining machines, drilling rigs, logging machines, coal mine supports, fuel dispensers, car washing machines, charging piles, and other engineering and agricultural and forestry machinery. They are mainly installed on the outside of hydraulic hoses, oil pipes, cables and other products to protect them from bumping, abrasion, explosion and corrosion in various harsh environments, thus prolonging their service life.

Company cooperation unit

Zoomin, XCMG, Futian Reza, Lingong, exported to, Russia, Brazil, Spain, Singapore, Canada, and other countries.

Production strength

Related Products

Key words: